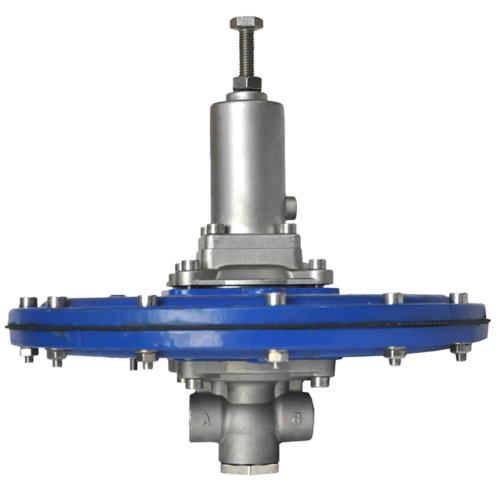

Hydromodul Anti Hammer Valve

The valve shall be made according to these specifications:

- high hydrodinamics section globe body, without stagnation pockets (low pressure loss type);

- standard ductile cast iron casting GS500/GGG50, carbon steel casting on request;

- 200°C furnace polyester powder paiting with 250 micron of minimum guaranteed thickness;

- plunger shaft entirely guided;

- particular plunger disc section and seat against cavitation risk;

- plunger shaft guide independent of seal seat;

- removible optional stainless steel seat, for higher cavitation resistance;

- obstacle free full port;

- neither spoke nor gride interposed in closing passage section to reduce maintenance and possible clogging;

- optional assembly of dissipating cage obturator without valve modification, to dissipate higher pressure and stabilize the valve opening;

- stainless steel shaft and return spring;

- return spring must not be inside flow path to avoid further turbulences and clogging;

- stainless steel bolts fastening cover to main valve body;

- nylon reinforced Buna-N diaphragm,

- antiabrasion Polyurethane plunger seal disc;

- easy maintenance design and easy access to internal parts without removing the valve from the pipeline;

- easy maintenance system, shall not be present any

- connection between the main body valve and the control circuit All the pressure or command connection shall be connected only over the cover of the valve;

- possible maintenance intervention on pilot circuit even with operating valve;

- drain plug (optional) on valve bottom for total drainage in case of frost;

- main function pressure gauge for pilot calibration included, optional pressure gauge on demand;

- valve functions can be changed or added by simple pilot circuit modification

STANDARDS CONFORMITY

- Flange to flange: UNI-EN 558-1, DIN 3202 serie F5

- Flange drilling: ISO PN10-16, on request compatible ANSI 150-300

- Conform to use with water intended for human consumption as DM174/GU166/DE98/83CE